TAMSYS India now manufactures a range of high-quality, high-reliability terminal accessories and equipment for large field equipment and integrated chain systems. The new product range, TECHNICA, includes switches, wires, PCBs, jacks, pin headers & other assemblies.

Technica

What is TECHNICA?

Why TECHNICA for CAPEX and OPEX initiatives?

Unplanned downtime costs industrial manufacturers an estimated $50 billion each year. (Source: WSJ Custom Studios & Emerson)

We noticed that the lack of local availability of accessories like switches, wires, PCBs, jacks, pin headers & other assemblies often result in production equipment staying idle on assembly lines.

Long maintenance timelines for equipment or projects stuck in construction for lack of connectors or damaged accessories causes project overruns and impacts bottom lines during production.

Ensuring continuity in production operations at the plant level is mission-critical to avoid spiralling CAPEX or OPEX costs across asset-intensive industries like automotive, heavy engineering, steel, or chemicals.

To provide a quick and efficient fix, TAMSYS India decided to undertake local manufacturing of a range of connectors, switches, actuators, and other accessories that will help businesses avoid downtimes or delays due to eroded or non-availability of parts.

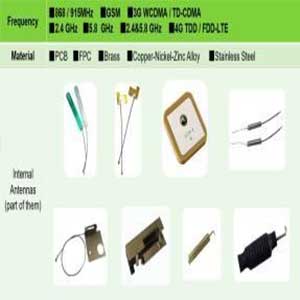

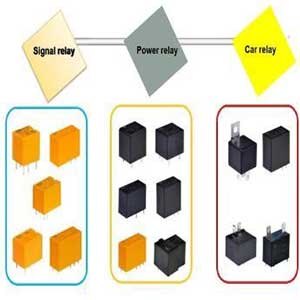

Take a look at the TECHNICA range of products and contact us for details and ordering information.

What are the different products?

What value does TAMSYS bring to the table with these products?

As they say, the team is as strong as its weakest link.

TAMSYS India has an integrated approach to engineering, design, supply, and maintaining equipment.

We are your go-to experts for custom-manufactured terminal accessories for large field equipment and integrated chain systems. Assured quality, on-time delivery and expert installation are the hallmarks of TAMSYS India, making us the preferred partner for chain systems and accessories.

- Our consultative approach towards solutioning helps our clients create value from installation and operations perspective

- Our integrated approach to deliver a engineered, import & manufactured fully assembled packages as an single point responsibility vendor helps gain on supply chain benefits like compressed delivery time frames & installed costs

- TAMSYS experienced teams in industrial & heavy engineered product manufacturing with over 200000-man hours helps our clients build & manage assets in the most cost-effective manner

Contact us

Get in touch with us

We are an ISO 9001:2015 certified company. Reach out to us for high-quality chain systems, dynamic protection for cables and hoses. Turn to TamSys for onsite service requirements to troubleshoot existing chain systems, reduce downtime and increase the longevity of your equipment.

Call us

+91-9527233000

Email us

info@tamsysindia.com